Peter Piechocniski is an Electro-Mechanical expert with 30 years in physical engineering of machinery, automation, and materials.

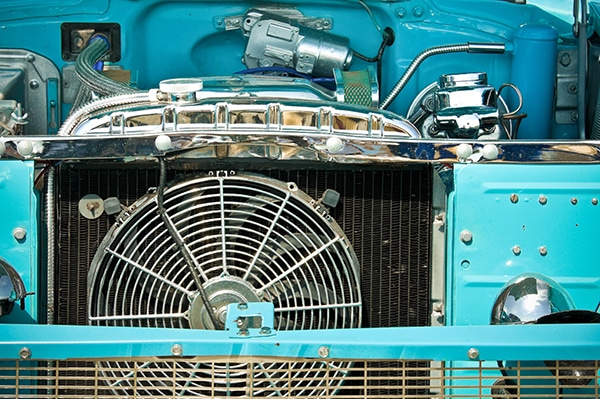

Comp-X, our flagship product, is a heat exchanger used for a variety of cooling and heating challenges. We all use heat exchangers. If you drive a car with a radiator, have an air conditioning unit, refrigerator, or hot water heater, you have a heat exchanger in your life. Current heat exchangers are an old technology that is reliable and readily available, but composed of metal and remains bulky, space consuming, and heavy. Our technology offers a novel, lightweight, structural, and conformable solution for use cases in which thermal loads, size, and weight constraints are continually increasing.

Liquid Channels is a company founded by professionals that are engineering by trade, but entrepreneurs by heart, focused on pushing technology forward for both defense and commercial industries. Our mission is to provide quality heat exchangers for more efficient solutions to enable emissions free, battery powered solutions for the future of mobility for people, goods, and information.

Modern technology in high performance applications will require advanced methods for dissipating heat. Three problems limit the potential of current heat management:

As heat loads increase due to the implementation of modern batteries, power electronics, or other heat rejecting equipment, space and weight constraints will increase. Modern heat exchangers need to be developed and improved to provide designers and engineers options for transferring thermal energy more efficiently to keep pace with new technology and its associated need for heat dissipation. Comp-X can achieve necessary thermal efficiency while providing substantial weight and space savings, and because of this innovation it is uniquely positioned to capture the shift in the mobility industry to battery powered options.

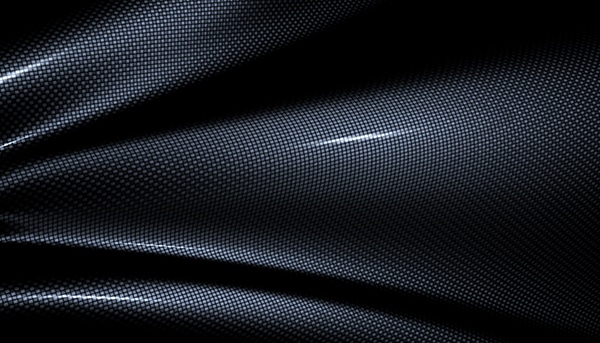

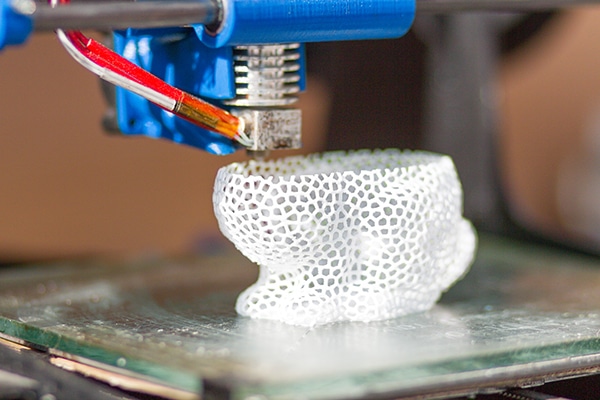

A concept developed and tested in the Naval Research Laboratory, the Comp-X is a dual network fluid heat exchanger built into plies of composite material. The composite construction offers novel space and weight savings with the required thermal transfer characteristics designed to meet customer needs. The inlet and outlet fluid connections are attached in manufacturing and can be any standard fluid connections (pipe, compression, push to connect, quick connect, etc) to fit a customer specific application.

The construction from composite material can also provide a customer a unique ability to customize the shape for structural applications and to maximize thermal transfer for space requirements, capable of filling a highly specific customer need.

The utility of a lightweight, conformable, and efficient heat exchangers has an extremely wide variety of use cases across defense and commercial applications. Through extensive customer discovery and first-hand accounts, battery cooling and heating requirements have changed dramatically over a very short period of time and require new heat management innovation to support the rapid development.

Specifically, Comp-X will target battery powered commercial aerospace. Innovation in mid-range aerospace and drones for transporting people and goods are requiring a dramatic decrease in weight to boost the range of vehicles.

From the defense sector, Liquid Channels is working to customize the technology to best enable satellites and spacecraft to minimize heat loss in the system. The heat exchanger technology will be focused on efficiently transferring heat and cooling between electronics and solar panels in a space environment that can range over 200°F.

Peter Piechocniski is an Electro-Mechanical expert with 30 years in physical engineering of machinery, automation, and materials.

Dusty Stahl is a mechanical engineer by trade and a Design and Release engineer based in Michigan, with experience in the automotive and transportation industry.

Tom Levac is a business leader and marine engineer with experience in US Navy technology transfer, all aspects of ship design, and hybrid mechanical electrical propulsion.

Peter Piechocniski is an Electro-Mechanical expert with 30 years in physical engineering of machinery, automation, and materials.

Dusty Stahl is a mechanical engineer by trade and a Design and Release engineer based in Michigan, with experience in the automotive and transportation industry.

Tom Levac is a business leader and marine engineer with experience in US Navy technology transfer, all aspects of ship design, and hybrid mechanical electrical propulsion.